Iron Ore Pelletizing Process: An Overview

The iron ore pelletizing process consists of three main steps: 1. Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives anthracite, dolomite and binders are prepared in terms of particle size and stone specifications, dosed, and mixed together to feed the pelletizing process; 2.

Iron Ore Pelletizing Process: An Overview | IntechOpen

Jul 10, 2017 · Induration process: the green pellets are hardened in a high temperature processing at controlled heating rates, and aiming to achieve the physical and metallurgical requirements for handling, transportation, and final application. This chapter aims to provide an overview and the evolution of iron ore pelletizing process including:

Iron Ore Pellets Induration Solutions - Metal 7

Iron Ore Pellets Induration Solutions. Iron ore green balls are soft and easy to break. So after the pelletizing and screening operations, iron ore pellets have to be hardened in a furnace through a firing process. Once fired, they can be handled, loaded in ships or trains and delivered to the end users.

Introduction to Iron ore Pellets and Pelletizing processes ...

Process technology. There are four stages involved in the production of iron ore pellets. These stages consist of (i) raw material preparation, (ii) formation of green balls or pellets, (iii) induration of the pellets, and (iv) cooling, storage and transport of pellets.

Recrystallization of Fe O During the Induration of Iron ...

Recrystallization of Fe 2 O 3 During the Induration of Iron Ore Oxidation Pellets 331 the dry balls were put into a corundum crucible and pushed into the preheating zone of the furnace step by step, preheated at the given temperature for a given period.

Iron ore pelletizing systems - liming

Both straight grates and grate kilns dry the pellets out in a drying section, then bring the pellets up to a temperature of about 800-900 °C in a preheat zone, then finish the induration process at roughly 1200-1350 °C. The pellets are then cooled to a suitable temperature for transporting to a load out facility.

Interaction between iron ore and magnesium additives ...

Feb 01, 2020 · In order to clarify the interaction between additives and iron ore during the induration process of pellets, interaction couple experiments [21,22] were conducted and diffusion performance of elements was studied. It is aimed to lay a theoretical foundation for the improvement of additive mineralization and promotion of pellets.

Study of the induration phenomena in single pellet to ...

Oct 01, 2013 · The process for pelletizing iron ore fines is an important operation unit for producing high quality of raw materials for the subsequent reduction processes such as blast furnace or direct reduction. The process essentially involves production of green pellets and induration on a traveling grate furnace to promote inner partial melt and ...

Rotary kilns - liming

Grate-Kiln iron ore pelletizing system provides process flexibility. Features. There are two main processes for producing iron ore pellets: The Grate-Kiln system and the straight grate system. In the straight grate system, a continuous parade of grate cars moves at the same speed though the drying, induration and cooling zones ...

(PDF) Iron Ore Pelletizing Process: An Overview

Oct 06, 2017 · This chapter aims to provide an overview and the evolution of iron ore pelletizing process. ... for the moving grate induration of iron ore …

Iron Ore Processing for the Blast Furnace

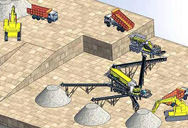

blast furnace process. The iron ore concentrate is now mixed and ready for the pelletizing process. Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" and 1/2").

Agglomeration of Iron Ores - 1st Edition - Ram Pravesh ...

Aug 23, 2019 · 2.3 Genesis of Iron Ore. 2.4 Classification of Iron Ores . 2.5 Mineralogy of Iron Ores . 2.6 Preparation of Iron Ores . 2.7 Industrial Practice on Iron Ore Beneficiation and Process Flow Sheets. 2.8 Handling of Iron Ores. Chapter 3: Iron-Making Processes . 3.1 Preamble . 3.2 Reduction of Iron Oxide . 3.3 Direct Reduction Processes . 3.4 Blast ...

liming –– Iron Ore Pelletization Iron Ore ...

liming –– Iron Ore Pelletization Iron Ore Pelletization The Right Choice Steven Steven FuredyFuredy –– Product Manager Iron Ore PelletizingProduct Manager Iron Ore Pelletizing ... -Final point of pellet induration in grate kiln system ... function of ore and fuel, same for either process SOx emissions are a function of ore and fuel,

Induration Process In The Iron Industry - Mczb Heavy Machinery

Induration process in the iron industry. iron ore induration process . iron ore pellet plant process SAM CrushersJaw Crusher . With gradual depletion of high Iron Ore reserves the Iron and Steel Mathematical model for a straight grate iron ore pellet induration process of

straight grate induration process for iron ore pelletizing ...

Iron Ore Pellets Induration Solutions Metal 7. Iron ore green balls are soft and easy to break So after the pelletizing and screening operations iron ore pellets have to be hardened in a furnace through a firing process Once fired they can be handled loaded in ships or trains and delivered to the end users Two indurating furnace technologies dominate the pelletizing industry the …

Chinas trade dispute with Australia has not extended to ...

13 hours ago · Despite all the tension between the two countries, iron ore sales to China in the first half of 2020 were actually up more than 8 per cent, …

Iron Ore Price Strength Generates Significant Offtake ...

Full mineral resource details can be found in the NI 43-101 compliant technical report entitled "Preliminary Economic Assessment of the Re-scoped Shymanivske Iron Ore …

Mining firm Vale completes first iron ore sale via ...

Sep 04, 2020 · Brazilian mining giant Vale has completed its first sale of iron ore using blockchain technology. The transaction with Nanjing Iron & Steel involved a cargo of 176,000 tons of material from Teluk ...