pelletising and sintering of iron ore - tiglon.nl

PELLETISING AND SINTERING on VimeoMay 03, 2013 PELLETISING AND SINTERING. Pelletizing is the process of compressing or molding a material into the shape of a p

sintering and pelletizing process of ore preparation …

iron ore His process involved grinding taconite to remove gangues and upgrading the iron ore (ie, an ore beneficiation process) The resultant high-grade ore is in the form of fine particles, as small as 01mm or less, which are not suitable for sintering This issue led to the use of pelletizing Pelletizing plants are expected to play an

sintering and pelletization of iron ore process

Iron Ore Pelletizing - FCT Combustion : FCT Combustion. Iron ore is the raw material used to make pig iron which is one of the main raw materials ... and have set the benchmark when it comes to iron ore processing. ... of burners are specifically designed for iron ore sintering and pelleting plants.

Ore Sintering - an overview | ScienceDirect Topics

02-04-2010 · Like other sintering processes, iron ore sintering converts iron ore fines of often − 8 mm sizing into larger agglomerates, namely, sinter, between 5 and 50 mm particle size, which possess the physical and metallurgical characteristics and gas permeability required for efficient blast furnace operation. As shown in Figure 14.1, iron ore sintering is carried out in three stages: raw material ...

Sintering: A Step Between Mining Iron Ore and …

11-06-2019 · The remaining 2% of domestic iron ore was produced for non-steel end uses. Seven open-pit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one direct-reduced iron (DRI) plant and two hot-briquetted iron (HBI) plants— operated during the year to supply steelmaking raw materials.

Leading Supplier for Iron Ore Pelletizing …

CVIC Group is a leading supplier specializing in R&D, manufacturing, and sales of iron ore pelletizing and sintering plant equipment and industrial ceramics. Its manufacturing Centre is located in Tangshan, in the province of Hebei, China, which is the largest steel-producing city and one of the most important heavy industrial cities in China.

SINTERING AND PELLETISATION OF INDIAN IRON ORES

Iron ore sintering creates substantial off-gas volumes, and treating these in order to meet increasingly stringent environmental standards is expensive. EOS® uses recycling technology to reduce off-gas volumes by 40 to 50 %, resulting in smaller secondary gas treatment

machine sintering and pelletizing iron ore

Iron Ore Agglomeration Processes and their Historical . Dec 28 2015Though a large numbers of improvements have been made since then in the machine mechanical design and in the process of iron ore sintering still the basic principle of the process remains the same History of pelletizing Pelletizing differs from sintering in that a green unbaked pellet or ball is formed and then hardened by ...

What is the difference between pellets and sinter? …

What is Pelletization? The process of Pelletization helps converting Iron Ore Fines into “Uniform Size Iron Ore Pellets” that can be fed in the blast furnaces or in the DRI kiln (DRI). Why Pelletization? Pelletization is the only answer to a major...

Iron Ore Pelletizing Process: An Overview | …

10-07-2017 · The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter shows the status of the pelletizing …

Iron Ore Production Sintering Pelletising

Sintering Vs Pelletizing Iron Ore vollendam. sintering vs pelletizing matiya.co.za. Iron Ore Sintering and Pelletizing Capabilities will show a relation to fired pellet quality at relatively low cost and can be used to identify firing cycles or addition >> Get Quotation. sintering and pelletisation of indian iron ores IIM Delhi. fines (sintering or pelletising). 3 into pellets suitable to feed ...

Sintering Vs Pelletizing Iron Ore - vollendam.nl

Iron Ore Sintering and Pelletizing Capabilities will show a relation to fired pellet quality at relatively low cost and can be used to identify firing cycles or addition >> Get Quotation. sintering and pelletisation of indian iron ores - IIM - Delhi. fines (sintering or pelletising). 3 into pellets suitable to feed Blast Furnace or Direct The pellet bed on the grate is only 150

sintering and pelletizing of iron ore

sintering and pelletizing of iron ore Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc., and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing process.

Pelletising Iron Sintering - tropischwinkelnazir.nl

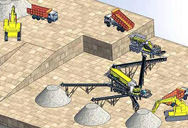

Pelletizing and Sintering Pelletizing of raw material by combining agglomeration with thermal energy is increasingly being used as a method of value adding Pelletizing is typically used in the iron ore industry to convert raw ore into pellets with characteristics appropriate for use in a blast furnace.

iron ore pelletization sintering - pmudekleineprins.nl

iron ore sintering and pelletizing mantelzorgleiderdorpnl. Iron ore pellets are marble sized balls of iron ore that are fused with clay for transportation and used in steel manufacture The process of making pellets from iron ore is called pelletizing The manufacture of steel from a low grade iron ore involves processes like mining crushing ...

Pelletization of iron ore - YouTube

18-04-2018 · Watch how Pelletization of iron ore can lead to energy savings of 126 TJ with a 50% increase in sponge iron production annually. United Nations Development P...

iron ore sintering and pelletizing

Sintering And Pelletizing Process Of Ore Preparation Pdf. 2020-5-5 Iron ore pelletization rotary kiln pdf.Iron ore pelletizing, gratekiln process, magnetite oxidation, rotary kiln, process modelling vi vii.Pelletization and sintering sintering and pelletization are the most important agglomeration and fed into a rotary kiln, where the material is tumbled at 62 iron ores and iron oxide ...

Iron Ore Production Sintering Pelletising - Vollendam

iron ore production sintering pelletising. iron ore sintering technology XSM excellent mining crushing machinery products or production line design the company is committed to building the Chinese brand mine crushing and processing machinery mainly crusher mill sand making our products iron ore sintering technology in more than one hundred of the worldsales of countries and regions.