Grinding Process Tephros - angelverein-werdau.de

Grinding Process Tephros. Sep 11 2017 we will provide you with the prior plan process flowchart design and production equipment in line with your special needs is dedicated to provide a complete line of equipment including shaking table spiral chute jig machinetrommelrotary scrubber …

Grinding Mill Equipment Used in Tephros …

Tephros Grinding Process. Grinding is the process of breaking crushed materials into fine powder size. Through the bucket elevator, the materials will be taken into the storage bin and then will be taken into the main grinding machine evenly through the electro-vibrating feeder. The materials will be scooped up into the grinding roller and ring ...

Which Type Of Ball Mill Used In Quartzite Grinding …

Grinding Mill Equipment Used In Tephros Production . 2018-8-30vertical roller mill used in tephros grinding processertical roller mill is the new type grinding mill used in tephros grinding processt is produced by limings professional expertshis kind of machine occupies high technology and is based on over 20 years grinding mill production experience.

Cement Grinding Mill Line In Canada Crusher For Sale

Grinding Mill Equipment Used in Tephros ... Chat Online. sand ball mill machine for sale canada – Grinding … ball mill gold grinding machine – process crusher. hammer mill for sale; Sand Making Machine. building sand making line in … of 130 nations, for example Russia . Chat Online. PRODCUT.

roller mill used for limestone grinding process

Limestone Grinding-South Africa Impact Crusher Price. Limestone Raymond Mill , Due to the centrifugal force during rotation, the grinding roller swings outward and presses against the grinding ring, so that the blade shovel the material to the grinding roller and the grinding ring The roller is rolled and rolled to achieve the purpose of pulverizing the material , Gold Ore Refining Process .

Used Vertical Grinding Mill Equipment Sale - …

2018830Vertical Roller Mill Used In Tephros Grinding Process. Vertical roller mill is the new type grinding mill used in tephros grinding process. It is produced by limings professional experts. This kind of machine occupies high technology and is based on over 20 years grinding …

Grinding (abrasive cutting) - Wikipedia

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.. A wide variety of machines are used for grinding: Hand-cranked knife-sharpening stones (grindstones)Handheld power tools such as angle grinders and die grinders; Various kinds of expensive industrial machine tools called grinding machines; Bench grinders

TYPES OF GRINDING PROCESS - Mechanical …

Through feed grinding process is considered as quite productive as grinding process could be performed simultaneously for number of objects. In-feed grinding If we have a workpiece, which has not exactly not right circular cylindrical shape, in this situation we will prefer in-feed grinding process as grinding wheel could be dressed according to the workpiece surface.

Grinding Machining Process : Complete Notes - …

23-12-2018 · The grinding process has the least material removal rate among other machining processes because of the following reasons- Size effect: As above discussed the machining is done by the abrasive action of grinding wheel that’s why a large portion of the abrasive will be embedded inside the wheel and a small portion of abrasive will be allowed to interact with them , therefore, less material …

Grinding and Finishing - IIT Mechanical

Grinding – Ex. 1-1 • You are grinding a steel, which has a specific grinding energy (u) of 35 W-s/mm3. • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2. The motor has a power of 2 kW. • The work piece moves (v) at 1.5 m/min. The chip thickness ratio (r) is 10.

Sand Making Machine - Bhopal grinding …

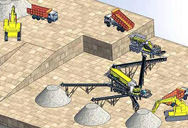

Grinding Mill Processing Plant Grinder Process. Sandstone Grinding Machine Quartz Grinding Limestone Production Line Limestone mining process can be included into three steps crushing screening and grinding In the grinding limestone production line we always use jaw crus Calcium Carbonate Powder Mill For the past few years with the rapid ...

line grinding process equipment

Grinding Mill Equipment Used in Tephros Production . 2018-8-30 Vertical Roller Mill Used In Tephros Grinding Process. Vertical roller mill is the new type grinding mill used in tephros grinding process. It is produced by s professional experts.

Grinding Machine: Types, Parts, Working & …

In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley.. So when we start the electric motor the motor rotates at a certain rpm (150-15000 RPM, it may change according to the types of grinding machine) with the help of v-belt and cone pulley the grinding wheel also starts rotating and we perform the operation.

Grinding Process, Finish Machining, Aerospace …

Grinding Roughs Out a New Niche Tyrolit Advocates a Patented Grinding Process for Rough and Finish Machining of Aerospace Parts. In the past, grinding has been a process that was primarily relegated to machining for final dimension accuracy and surface finish.

What is Grinding? - Definition from Corrosionpedia

13-06-2018 · Grinding is a subset of cutting, as grinding is a true metal-cutting process. Grinding is very common in mineral processing plants and the cement industry. Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension.

Basics of Grinding - Manufacturing

grinding machines perform the dressing task automatically. The application of coolants to the grinding process is important. Coolants reduce grinding machine power requirements, maintain work quality, stabilize part dimensions, and insure longer wheel life. Coolants are either emulsions, synthetic lubricants or special grinding oils.

Grinding (Machining) - an overview | ScienceDirect …

As the contact area is less, EC cylindrical grinding is a slower process. Typical values of ECG operating parameters are given as follows: DC Power Supply Voltage: 4 to 14 V; Current: 50 to 3000 A; Electrolyte Type and Concentration: NaNO3 (120 to 140 g/L), KNO3 (180 to 240 g/L), NaCl (60 to 180 g/L); Abrasive Wheel: Conductive; Abrasive: Al 2 O 3 or diamond grit, Speed:4000 to 7000 rpm (1200 ...

grinding mills for the process industry

Grinding Mill Suppliers,Grinding Mill Machine,Raymond mill ... Find here Grinding Mill ... Precise Process ... which is designed specially to solve the problems of low capacity and high consumption of traditional industry mills.

GRINDING AND OTHER ABRASIVE PROCESSES

Grinding is most important abrasive process Other abrasive processes: honing, lapping, superfinishing, polishing, and buffing . MECH4950 Advanced Manufacturing Technology - Dr Ghassan Al-Kindi Why Abrasive Processes are Important Can be used on all types of materials